B13 Sentra Brake Upgrade Install Instructions

1. Assemble the proper parts and tools. You'll need a new brake master cylinder from an NX2000 (unless you already drive an NX), new front rotors, new front calipers, pads and shims. Additionally, you'll need a set of metric open-end wrenches or a ratchet set, a 10mm flare nut wrench, a jigsaw, rotary (Dremel) tool or other tool suitable for cutting sheet metal, a brake bleeder hose, and a couple of pints of brake fluid. You may also want to have a long-handled pipe wrench or torque wrench handy, in case some of your bolts are on too tight for a standard wrench. If your car is a Sentra SE-R and you plan to use stock wheels, you need to grind 1.5 - 2 mm off the outside edge of the calipers in order for them to fit (a machine shop will be happy to do this for you, for a few dollars). After the calipers are ground, paint them with 500 degree paint to inhibit rust.

Master Cylinder

Place a thick layer of shop towels under the brake master cylinder. It's located just inboard of the left front shock tower. There are four metal tubes that run out of the MC; these are your brake lines. Using a10mm flare nut wrench, disconnect these tubes from the MC. The tubes are filled with brake fluid and some will leak out -- that's why the shop towels are there. The nuts that hold the tubes on are quite tight, so it'll take some muscle to get 'em off. You may find it convenient to remove your air intake box to get easier access to some of the tubes.

Once the brake lines are disconnected, you can remove the MC. Along the firewall, two bolts hold the MC to the brake booster. Unfasten these, holding the MC steady as you do the last few turns. Carefully remove the old MC from the car; you don't want to spill fluid if you can avoid it. (Note: if one is available, you can use a turkey baster to remove brake fluid from the reservoir atop the master cylinder. However, the author is not responsible for any domestic conflict that may result from this act).

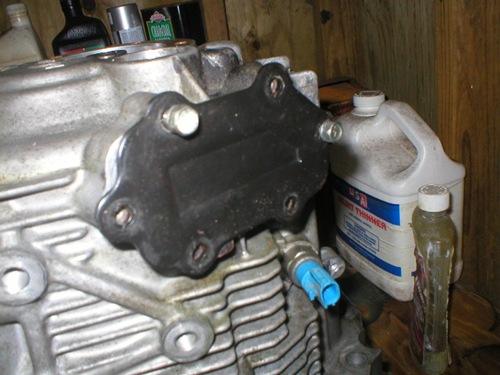

Pour some new brake fluid into the reservoir of the new MC. Actuate the pistons by sticking a screwdriver into the hole in the MC and gently pressing harder. Pump the pistons until fluid starts to ooze out of all 4 holes on the MC. Now, reverse the removal process to install the new MC. Bolt the MC to the booster, then attach the brake lines. Your "heart transplant" is complete; you can now move on to the calipers.

Calipers/Rotors

Jack up the car at the front and remove both front wheels. Inspect all parts so you'll have a good understanding of what you're about to attempt. If you look into the wheel well, the rotor is the big thick metal disc that you're staring at, and the caliper is the black or grey metal piece that's clamped on to the rotor. The brake line joins the brake hose at the top of the wheel well, and the hose runs down to the back of the caliper, where it's fastened by a bolt. Actually, the caliper is really 2 pieces, the caliper frame or torque member which holds the pads, and the caliper proper, which contains the piston and which squeezes the pads when you step on the brake pedal.

First, loosen the bolt which fastens the hose to the back of the caliper. Don't take it off, just crack it a little bit so it's easier to turn. It's tough to get enough torque to take off that bolt once you've unbolted the caliper from the hub if you don't do this. Now, attach a piece of wire from the bolt you've just loosened to some convenient spot on the strut tower. This is to prevent the brake hose from stretching when you remove the caliper; if you don't do this, the caliper will hang by the hose after you unbolt it from the hub.

Now you're ready to unbolt the caliper from the hub. The caliper frame is fastened to the hub by two bolts; the heads of these bolts are behind the rotor. Unfasten them (this is where I needed a long-handled wrench). The caliper is now held in place only by the clamping power of the caliper itself, which is clamped onto the rotor. Wiggle the caliper assembly off the rotor and gently ease it into a position where it's hanging by the wire you've just fastened. Remove the rotor from the hub and set it aside; you don't need it anymore.

Grab one of the two new torque members from your new brakes (if it's attached to the caliper, just slide it off the slider bolts). Hold it up to the spot where you've just removed the old caliper and frame, where you'll be bolting it in. It won't fit! (That is, I know it won't, if your car is a Sentra. I have no knowledge of fit problems with the NX or the 200SX). The splash guard, a piece of sheet metal just behind where the rotor used to be, is in the way. Using the new torque member as a guide, cut away the sections of the splash guard that interfere with proper fit. Once this is done, slide a new rotor onto the hub and check to make sure that the splash guard doesn't contact the rotor. If it does, cut away any offending part of the splash guard. Some people advocate cutting off the entire splash guard, claiming that this will help cooling.

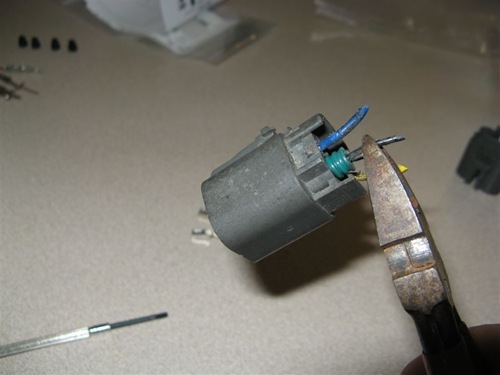

Now, assemble the caliper system. Slide the torque member onto the caliper, making sure that the slider bolts are well lubricated. Insert the new clips, shims and pads into your new caliper, using the old caliper as a guide for what goes where.

With the rotor on the hub, slide the caliper assembly onto the rotor and into place. Bolt it onto the hub. Now, remove the bolt that fastens the hose to the old caliper, which has been hanging by a wire all this time. Make sure you save both copper washers. Fasten this bolt, with washers as they were on the old caliper, onto the new caliper. You can now remove the old caliper and the suspending wire.

Obviously, you need to repeat this process for the other front wheel.

Bleeding the system

It's possible that during the installation of the master cylinder or the calipers, pockets of air have entered your brake lines. These will inhibit proper brake function and must be removed by bleeding the brake lines. Standard bleeding procedure requires two people, though three is preferable. Bleed the brakes in order:

1. Left rear

2. Right front

3. Left front

4. Right rear

Bleeding procedure: Jack up the car at the proper corner and remove the relevant wheel. Fasten a clear plastic bleeder hose to the bleeder valve on the caliper, and place the other end of the hose inside an empty soda bottle or other container. This tool is available for around $6 at any auto parts store. Open the bleeder valve with a 10mm wrench. One individual climbs (gently!) into the driver's seat and pumps the brakes. Another watches brake fluid coming out of the caliper through the bleeder hose. A third watches the fluid level in the reservoir atop the master cylinder, pouring new fluid into the MC as necessary. When new fluid is coming out of the hose with no air bubbles, close the bleeder valve. Repeat this procedure for each wheel. When you're done, the brake pedal should be rock hard. If it's "spongy", you've still got air in the system somewhere -- bleed it again until it's all out.

Source: Jim Wright/Don Dale