Well seeing as the stock o2 sensor wire is to short to reach the bung on the DET t25/t28 J-pipe I decided to make an extension that I could just plug in with out cutting or soldering. The best way to do this is to Crimp all the connections. AFAIK Soldering the connections is not the best idea because over time it will deteriorate from the elements and eventually crack and fail.

I put mine together using some connectors from a wiring harness I had lying around in my basement. If you go to the dealership you might be able to have them order a male and female connector but I’m not sure about that. I suppose you could also sweet talk a Junk yard guy into letting you snip a few connectors but I don’t see that happening.

So I do know for sure you can get the proper pins from the dealer for pretty cheap. This is where I got mine. I paid a whopping $0.08 for all of them (you need to make sure you get the ones that have the ring to hold the insulator on the end of them):

Now my dealer didn’t have the correct size insulators. You want to use the black ones because they are for 18-16 gage wire. I salvaged some good one from my wiring harness so I didn’t need to order any from them.

I cut a plug off my extra harness:

Pop the pins out with a small flathead screw driver:

And remove the pins with the insulators connected to them:

Removing the insulators from the pins was fairly easy. Just remember you want to reuse the rubber insulator part so be gentle with it.

This is my donor connector. (I had to cut the male end off a junk o2 sensor because my wiring harness only had the female connectors on them). I removed the pins from them and disassembled the connectors the same way as described above:

Now for the crimping needs you need to use a special terminal crimper. It’s specially designed to crimp Weatherpack terminals. I found this one on Ebay for approximately $30 shipped:

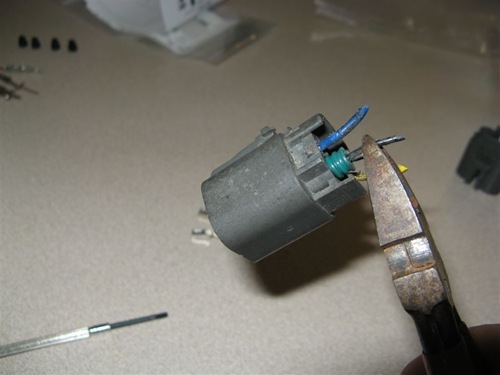

Although it was designed to crimp the Weatherpack "like" terminals I needed to modify it so I could use it to crimp the terminals designed with the insulator rings on them. It was pretty easy to do with the Dremel and a carbide bit. This is how the opposite side looked when I was finished (I decided to use the 16gage die crimp for these terminals.):

If you look around hard enough you can find the proper crimper for the job. They are designed to crimp terminals with the insulators on them but all the ones I found were $100 or more plus shipping. I’m cheap so modifying the one I got was the easier way to go.

So on to the crimping. First you need to get some wire. 18-14 gage should be fine. I’d stay on the smaller side because the factor wiring size looks like it’s about 18gage or so.

Now strip off about .25” of the wire insulation.

Slide one the insulator:

Assemble it so it’s ready to crimp:

And crimp it up!

This is how it should look after it crimped. Almost factory quality:

Now all you need to do is crimp up the rest of the wires, pop them back into the connectors, snap the black terminal keeper back on and cover the wire however you like.

I used some of the black wire sheath you can get from the auto store and I taped the ends up like they do with the factory wiring harness.

I made it about @ 14” long. I may redo it and make it longer but I won’t know for sure if I have to until I drop everything in.

Mike@sr20

0 ความคิดเห็น:

Post a Comment