Well, I started pulling my B15 tranny apart today to install my friction type LSD and thought I'd share with all of you a little bit of what I found. We all know that B15 trannys hold up to high HP way better than B13/B14 trannys and I've frequently seen many folks wondering what exactly is responsible for this. Unfortunately, there really hasn't been any definitive answer. Thanks to a friend of mine who has many torn apart B13 trannys, I was able to compare and spot some big changes in the B15 tranny. Hopefully what I have found will shed some light on the major differences. I am assuming that the P11 tranny is identical but I don't have one to compare with here.

What we already know:

There is some seperation of the input and main shafts under WOT that occurs in B13/B14 trannys. This puts a great deal of stress on the ends of the gear teeth (at its worst in 3rd) leading to shearing in high HP scenarios. The B15 tranny does not seem to have this problem and thus holds up much better to high HP applications.

But why?:

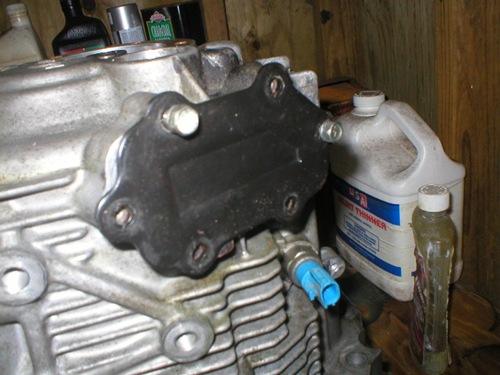

Obviously the B15 case is significantly different than B13/B14 cases. An addition that was made with the introduction of the B15 tranny is pictured below.

The two seemingly pointless 14mm bolts pictured actually serve a very important purpose and that is reinforcement. Inside the sleeves that they screw into is a small spring that holds pressure on a check ball (2 springs and 2 check balls total). The check balls contact the two shifter rods that 'ride' the main shaft and essentially hold tension on them when in place. The shifter rods are notched where the check balls contact them and you cannot even remove the case without removing those two bolts first. This is quite a nice improvement over the B13/B14 design where the shifter rods are loose at best. In addition to this, the shifter rod that 'rides' the input shaft sports a much beefier fork and sits with much more stability over the B13/B14 counterpart. Support, stability and reinforcement are obviously greatly improved.

As far as the internals go, everything is different, including the diff. IMHO, it seems like the gear stacks are beefier on the B15 tranny (see pic below). Sorry that I have no comparison pics with a B13 or B14 tranny.

Probably the biggest difference that sets the B15 tranny apart though is the positioning of the reverse idler gear. To get to the gear, you must take off the small cover pictured below, and remove its retainer pin (also pictured below). This gear is actually held into the tranny case itself (by the retainer pin) and meshes with the input shaft. It basically forces the input shaft to stay completely meshed with the main shaft, yet another reason why there is virtually no play in these trannys.

Reverse idler gear cover

Removing the snap ring to take out the retainer pin.

Threading a small bolt from the cover into the retainer pin to lift it out.

The actual retainer pin removed.

After the pin is removed, the reverse idler gear pulls right out of the case.

So to highlight how the input and main shafts stay meshed in the B15 tranny, I give you the following synopsis:

Input shaft: Supported on one end by the input shaft bearing and on the other end by the reverse idler gear and a better design rear bearing, thereby preventing play under WOT.

Main shaft: Supported on one end by the diff final drive gear and on the other by the spring-loaded check balls as well as the bearing race, thereby preventing play under WOT.

Hope this sheds some light on some big differences between the two types of trannys...

coalitionSE-L@sr20

0 ความคิดเห็น:

Post a Comment